Cable assembly

WAAK, the cable assembly leader

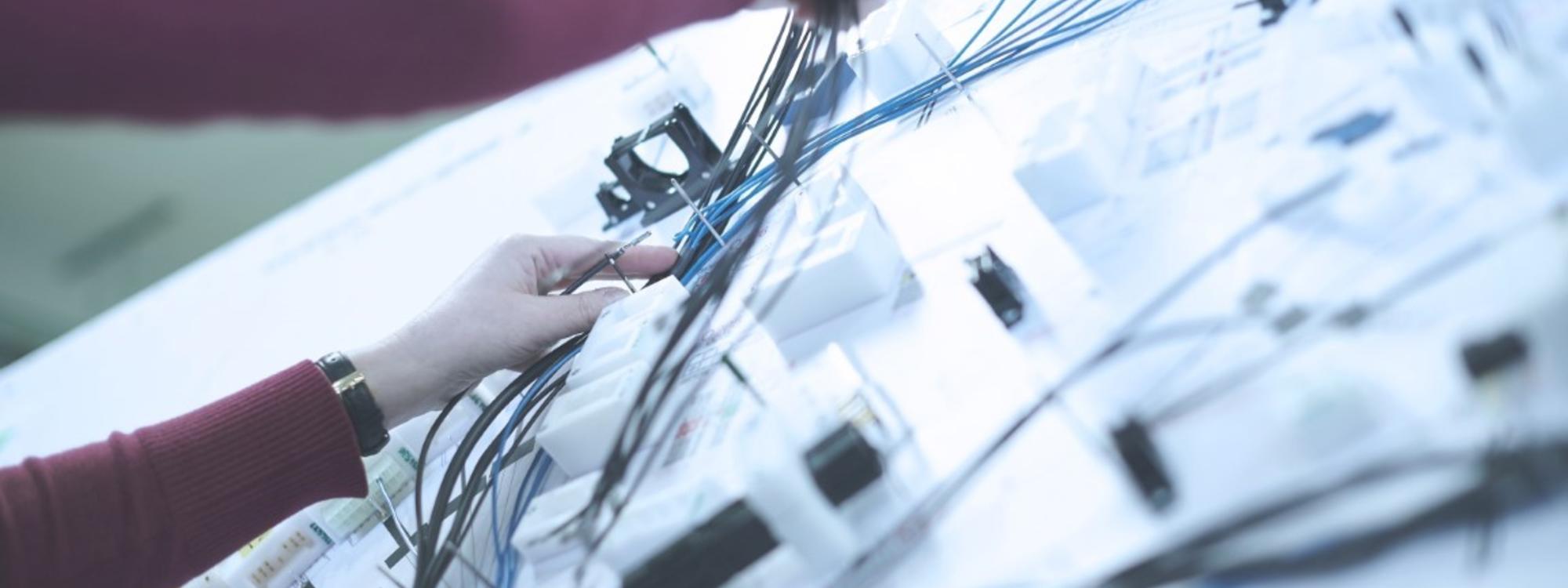

Cable assembly is precision work that requires both experience and expertise. Nowadays quality requirements are so demanding that zero defect is the industry standard.

With 55 years of experience, WAAK is your perfect cable assembly partner. We can handle large volumes of error-free serial work thanks to our automotive and HVAC industry experience.

Our greatest strength is that we’re capable of transforming complex and difficult assembly processes into simple ones. Complexity doesn’t scare us, we consider it a challenge we’re happy to take on.

As a social enterprise we mainly focus on sustainable collaboration. There are two reasons for this: on the one hand, it allows us to create long-term, future-oriented jobs for our employees. On the other hand, it allows us to go the extra mile for our customers: we can offer them a better service and far greater commitment than is customary in the assembly industry.

5 reasons why you should cooperate with WAAK:

- Impeccable production line work tailored to your product

- High-performance state-of-the-art machinery

- Technological support provided by experienced engineers

- JIT deliveries and deadlines are strictly followed

- High-tech quality control and LEAN optimisation

Customised precision work

As a social enterprise, we work in a very systematic and precise manner. Our cable-assembly system is a perfect example of how we meet industry zero-defect requirements.

Complex assembly processes are subdivided into simpler sub-tasks. They are executed perfectly thanks to our high-tech technological support systems such as pick-to-light-systems, camera recognition, on-screen instructions, systematic sampling, etc. Our work is flawless, and we are rightly very proud of it!

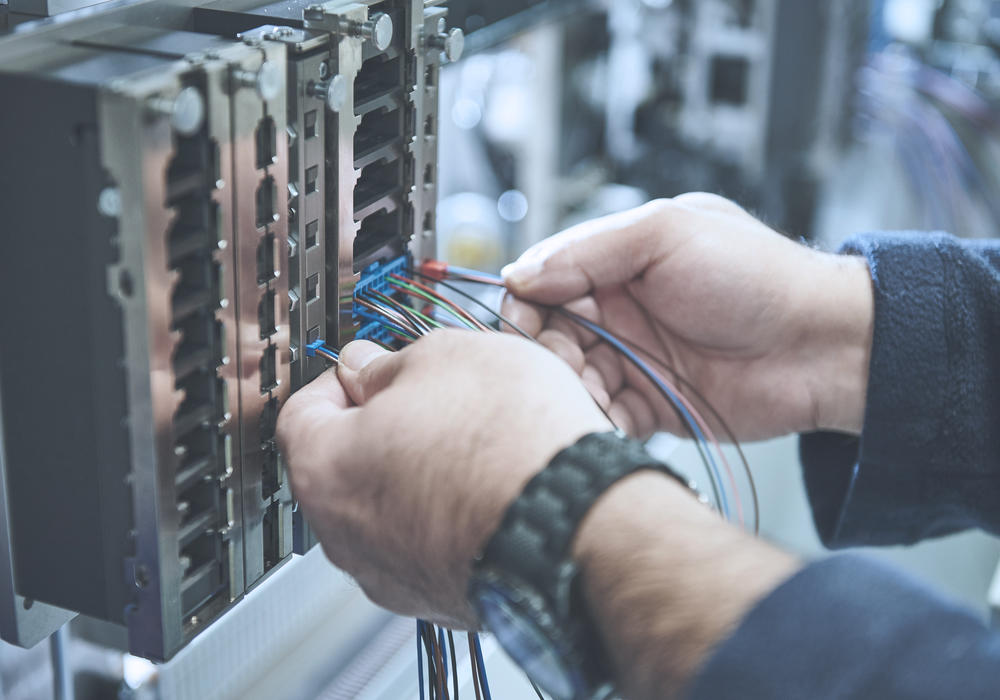

Let WAAK make your cable harnesses

Making cable harnesses, from control wire to power distribution, is our daily business. Thanks to our experience we are proud to say that we are among the best in the assembly industry.

We have all the technology in-house to ensure our customers get the perfect end product: functional testing of cable harnesses, high voltage testing, back pressure testing and camera testing.

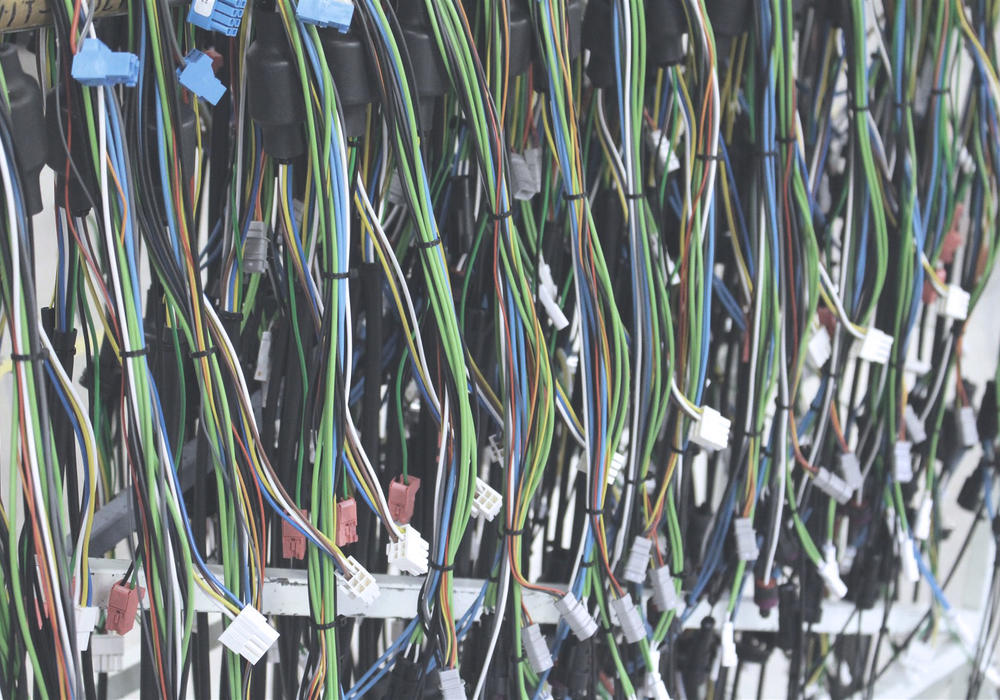

Expert production of HVAC pump cables

WAAK has extensive experience in the production of cables for major brands within the heating industry. As a specialised manufacturer of cables for circulator pumps, we are happy to set up a custom-made assembly line for you.

From the production of power cables or signal cables for PWM control, to full integration in a complex cable harness, the application of Hot Melt technology, encapsulation of connectors with PA-moulding, and even the creation of high or low pressure moulds, WAAK has all the HVAC know-how you’re looking for. Choosing WAAK means choosing a 100% Belgian company, with a low environmental impact.

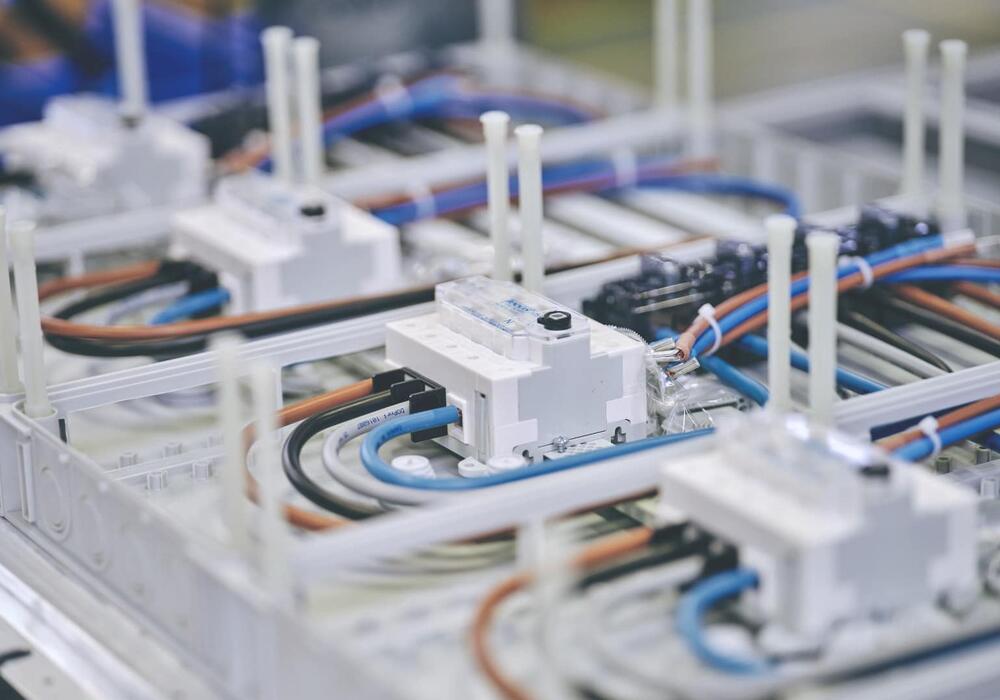

Assembly of high-quality power cables

WAAK operates a dedicated manufacturing facility for power cable manufacturing. Our power cables are used in smart meters and meter banks among others. To meet our customers' high-quality standards, we implement multiple thorough quality control processes. As such, our partners always get the product they want. Error-free and in time.

LEAN-systems with measurable timings

As a social enterprise we’re one of the first companies to introduce LEAN and poka-yoke systems. Consequently, our assembly processes are not merely focussed on error prevention, but are also designed to achieve the most efficient throughput.

Firstly, we thoroughly analyse every assembly order. We then make it as “lean” as possible, with the shortest possible lead time, respecting the specified quality requirements. This way of working allows us to adhere to strict deadlines.

Advantages of working with WAAK:

- Stringent scheduling and very high delivery reliability

- Extensive quality control

- Co-engineering support

- Supply chain expertise

- Advanced process optimisation

- A wide range of industrial services

- Extensive testing procedures

Our cable assembly services

- Wire and cable cutting

- Contact processing

- Cutting and clamping techniques

- Assembly and gluing

- Hot Melt technology

- Ultrasonic welding

In addition to manual cable assembly, we are also able to offer high performance machinery.

I love to hear more about your project.

Kristof Hots

Sales & Marketing Director

M: kristof.hots@waak.be

T: +32 56 36 34 34

Customer cases:

WAAK: 40 years of cable assembly for Vaillant Group

Since the 1980s, WAAK Cable Assembly and Vaillant Group have been working together. The German multinational, Vaillant, is one of the largest producers of HVAC systems (i.e. heating, ventilation, and air conditioning). WAAK started as a second-source supplier but, thanks to its reliability, quality, and innovation, quickly became a primary supplier. Today, WAAK manufactures complex cables and wire harnesses for products such as heat pumps and central heating boilers. Together, both companies continue to strengthen each other and set new standards in the HVAC industry.

Thermia: Scaling up without comprimising on quality!

Due to strong market growth, our customer, the Swedish (ground-source) heat pump specialist Thermia, needed to ramp up production while maintaining their very tight tolerances - a tough challenge!

That’s where WAAK stepped in, delivering flawless cable and wire harness assembly to meet both Thermia’s quality standards and volume demands.

Power cables for Fluvius' smart meters

For Flanders’ grid operator Fluvius, we assemble and provide electrical cabling for their smart meters and meter banks. Our power cable manufacturing approach is unique and thanks to the integration of multiple quality checks in the production flow, we achieve higher quality standards than what’s common in the industry.