5 reasons why outsourcing your manufacturing to WAAK is a good idea

Outsourcing all or part of your business manufacturing to a sheltered workshop can be very interesting for your company. It offers many advantages in terms of price, efficiency and quality. On top of that, WAAK also provides a comprehensive customer service. Clients of the WAAK sheltered workshop, the biggest in the province of West Flanders, benefit from its economies of scale. All our products and machines are under the same roof. This allows us to manufacture your products at a lower price and at a higher quality than if you were to do it yourself. We always explain our unique selling propositions (USPs) with a telling example.

Expertise and specialisation

WAAK specialises in cable assembly, plastic assembly, packaging and metal assembly. Companies that work their products in a specific way often need specialised, technical staff, which can be very hard to find in today's labour market. They also need specific machinery, which tends to require significant investment. WAAK has both all under the same roof. We have all the necessary machines to perform the most common processes and our 2,100 employees are trained to a high standard to handle your jobs without any problems. If your product requires complex processes, it is certainly a good idea to consider outsourcing its manufacturing. This is particularly of interest to companies that are used to outsourcing their manufacturing anyway. Several of our clients focus on product design and marketing only and outsource their manufacturing. The only manufacturing activities on their premises are the final inspections and adjustments.

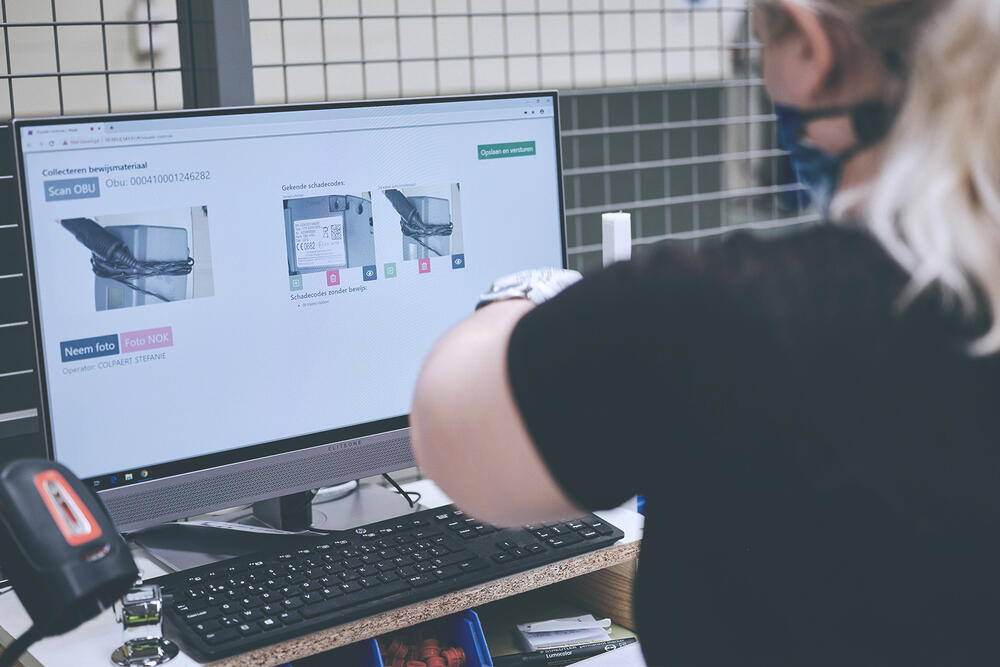

Highly complex work and high volumes are a perfect match for our staff: discover our OBU refurbishment project

Quality control

Our unique selling proposition for our clients is definitely quality. If your product is difficult to manufacture, requires significant manual labour and has one or more critical points in its production flow, we will know what to do. For more than 60 years, we have employed people who have difficulties accessing the labour market, and we are strongly committed to well-developed, extensive control systems. They make sure that errors in the production process are identified and ensure that the customer receives a final product that meets all quality requirements.

The quality of our end results is even better than the quality provided by regular companies: find out about the control systems behind the assembly lines of our meter banks

Cost savings

WAAK has 76,000 m² of production space and 2,100 employees. Companies that enter into a long-term partnership with WAAK benefit from its economies of scale. As a client, you don't have to invest in machinery and equipment, and the large volumes we handle will reduce your costs. If your product needs to be worked in multiple processes or you are looking for a combination of manual assembly and one or more machine processes, WAAK will likely be able to handle everything for you. This brings down the price, but also means you don't have to deal with any other companies, which makes things easier to coordinate and reduces the risks in terms of stock and quality.

Companies Smappee and Belintra both have their metalworking and (final) assembly done by WAAK. Find out how this benefits them.

Comprehensive service and excellent reliability

When a client outsources its manual work to WAAK, our co-engineers will take a close look at the production flow. As an expert in lean manufacturing, we know better than anyone how to set up a production line and in what composition. We make all the steps of the manufacturing process seamless. This benefits both the quality and efficiency of the end result. The product is ready sooner and any quality risks and production delays are eliminated in advance. All this reduces the costs and increases the client's return on investment (ROI). Besides production support, we also provide additional services such as direct product delivery at our warehouses, stock management and so on.

The packaging market is highly competitive. For our client Decathlon, we source the components ourselves and we receive direct deliveries. Our reliability, quality and comprehensive service really make a huge difference to Decathlon.

Sustainable, circular and inclusive: offers companies authenticity and credibility

As a company and SDG Champion, we are committed to making our production as sustainable and circular as possible. We like to partner up with like-minded organisations who share our vision. These companies don't see this as a cost or obstacle, but as an added value to their business. The fact that we employ people who would have little or no opportunities in the regular labour market is right up our clients' alley in terms of corporate social responsibility (CSR). It makes their business more authentic and adds credibility. And the knowledge that their product is created in a sustainable way makes it even more interesting to end consumers.

WAAK is collaborating with potato producer Agristo in a circular project that saves costs and reduces food waste. And the opportunities it gives to people who initially found it hard to access the labour market is the icing on the cake.

Let's discuss your project. Feel free to contact me!

Kristof Hots

Sales & Marketing Director

M: kristof.hots@waak.be

T: +32 56 36 34 34