AVASCO and WAAK Metal Assembly: a high-flying partnership

What began as a chance encounter at 10,000 metres has evolved into a sustainable partnership between AVASCO Industries and WAAK. The rapidly changing market for metal shelving systems presented AVASCO with new challenges, but thanks to the expertise, flexibility and ingenuity of WAAK Metal Assembly, a solution was found that truly gives both companies wings.

AVASCO Industries: European market leader in metal shelving systems

AVASCO Industries is a leading European manufacturer of indoor metal shelving systems, water storage tanks and sheet metal processing. These products form the company’s three divisions: AVASCO Shelving, AVASCO Water Storage and AVASCO Subcontracting. Although all divisions are based in Diksmuide (Belgium), the company is strongly export-driven. With a production capacity of more than 3.5 million shelving units per year (or 10,000 per day), AVASCO is the European market leader.

WAAK gives AVASCO wings… a partnership that started in the sky

The collaboration between AVASCO and WAAK began during a flight. By coincidence, Kristof Hots, Sales & Marketing Director at WAAK, was seated next to Jan Van Houtte, Managing Director of AVASCO, and they struck up a conversation. Their discussion soon turned to the activities of their respective companies.

From galvanised to powder coated: a market in transition

AVASCO Shelving manufactures metal shelving systems for indoor use. These systems consist of assemblies of various profiles. In the past, most shelving units were made from galvanised profiles (70%), while the demand for powder coated shelving systems was rather limited (30%). In the last couple of years, however, the situation has shifted completely. Today, most shelving systems are finished in a black or dark grey powder coating.

Powder coating capacity challenges at AVASCO

AVASCO had two powder coating lines available, but the shift in demand meant it was no longer possible to process everything on the same lines. To resolve these capacity issues, the Diksmuide-based company would have needed to introduce an additional night shift on its existing powder coating lines, which proved difficult to implement in the short term.

WAAK Metal Assembly’s powder coating lines as the solution

While searching for an alternative solution, Managing Director Jan Van Houtte recalled a flight he had taken several months earlier. He contacted WAAK and outlined his challenge: powder-coating approximately 35,000 profiles per week. As these are indoor products, we saw an opportunity in this.

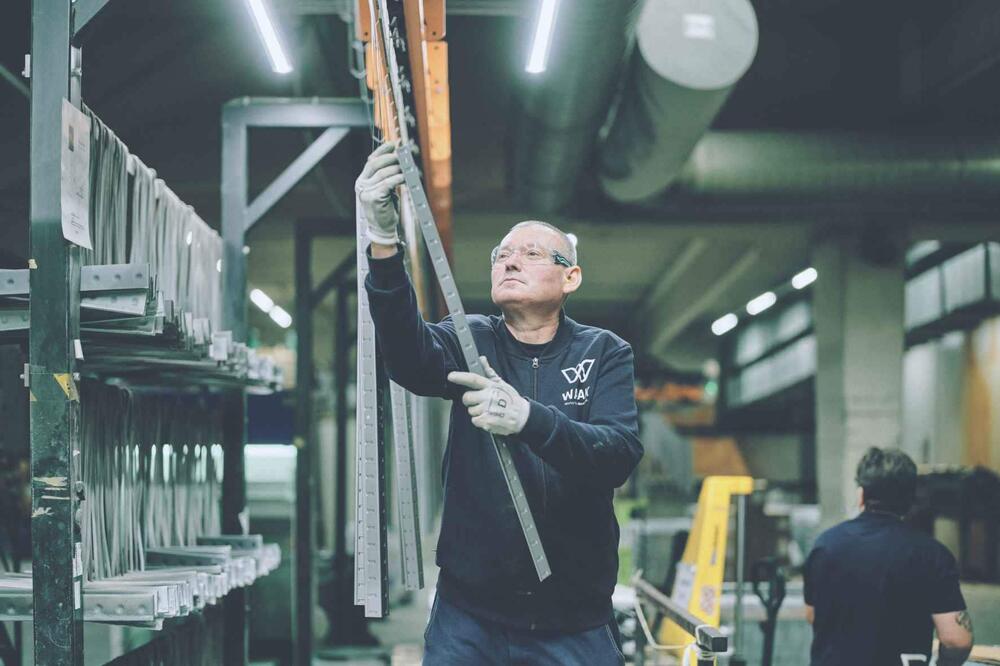

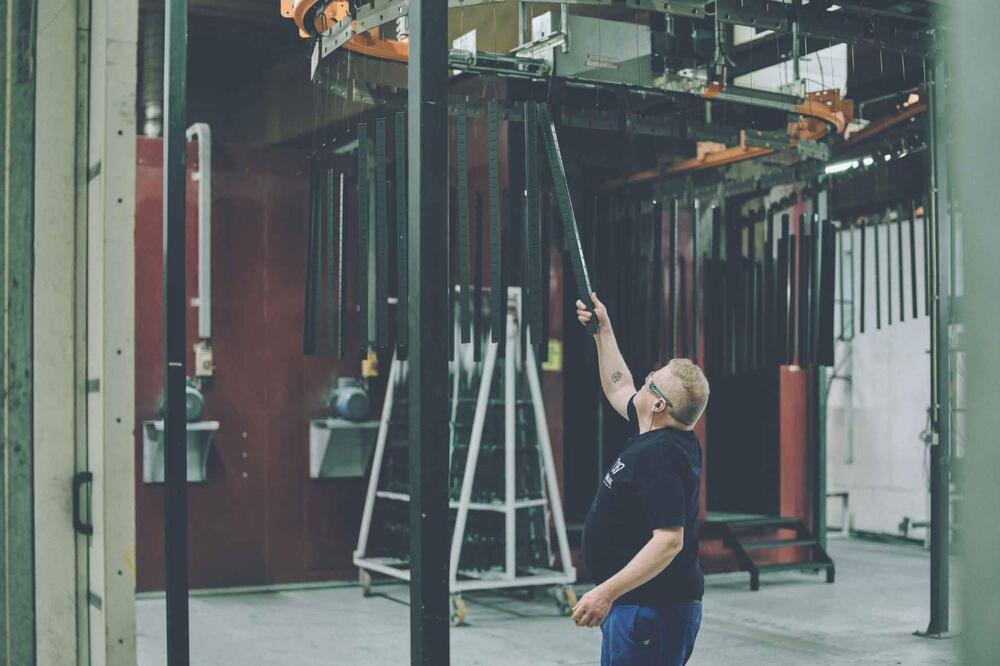

At WAAK Metal Assembly, we operate two powder-coating lines. One line is equipped to carry out an additional corrosion pre-treatment, which is used for outdoor products, such as the EV charging stations of Smappee. The other line does not offer this pre-treatment and is therefore ideal for processing the profiles of Avasco's shelving systems.

Turning a challenge into an opportunity

Given the high expected output, we carried out extensive testing in advance to determine the maximum achievable speed without compromising quality. We also assessed what volume would be manageable for our operators. As our second powder coating line is used less frequently, we were able to guarantee AVASCO eight hours of capacity per day.

Precision stacking thanks to a custom-made stacking jig

The only remaining challenge was the precise stacking of the profiles. This is essential, as the profiles are automatically picked and packaged at AVASCO. To ensure that our employees could position the profiles correctly, our co-engineering team designed a custom-made stacking jig. The result fully meets the customer’s expectations.

Scaling up together: Partnership with Avasco evolves

AVASCO is very satisfied with the results and has requested that we reserve production capacity through the end of 2026. Furthermore, the project has generated a spin-off: we will also provide powder coating for the connectors used in the same AVASCO shelving systems. A dedicated system will be implemented, allowing the connectors to be hung and removed offline using a detachable rack mounted on the line. This approach will enable us to achieve a significantly higher throughput capacity.

Tell me more about your project, I'm happy to help you out!

Kristof Hots

Sales & Marketing Director

M: kristof.hots@waak.be

T: +32 56 36 34 34