Circularity first: WAAK gives ExtraPower’s cables a second life

An increasing number of companies are exploring the opportunities offered by the circular economy. ExtraPower, a Beernem-based (near Bruges) company specialised in the installation of solar parks and EV charging infrastructure, is part of this growing trend. In this new domain, they draw on the expertise of WAAK Cable Assembly. ExtraPower found a solution for their leftover inverter cables. Employees of WAAK cut these cables into new, ready-to-use jumper cables. The latter are cables of 4 to 6 metres that connect solar panels to one another. This approach transforms surplus materials into valuable and functional products, demonstrating how circularity and profitability can be effectively aligned.

ExtraPower: From charging infrastructure to solar parks

The expertise of ExtraPower focuses on complete electrical solutions for the industry, such as the installation of charging infrastructure for electric vehicles, BESS solutions (Battery Energy Storage Systems), the construction of high-voltage substations, and the development of solar parks. It is primarily in this latter domain that WAAK Cable Assembly has entered into a collaboration with ExtraPower.

Solar parks: Sustainable energy tailored to the industry

An industrial solar park consists of thousands, tens of thousands, or even hundreds of thousands of solar panels that generate solar energy on a large scale. This is particularly attractive for medium-sized and large companies with a high electricity consumption, as sustainable energy is not only environmentally friendly, but also financially advantageous.

When installing a solar park, the solar panels must be connected to an inverter so that the direct current (DC), which is generated by the panels, can be converted into alternating current (AC) suitable for the electricity grid. For safety, the cables must be uninterrupted and made from a single continuous length.

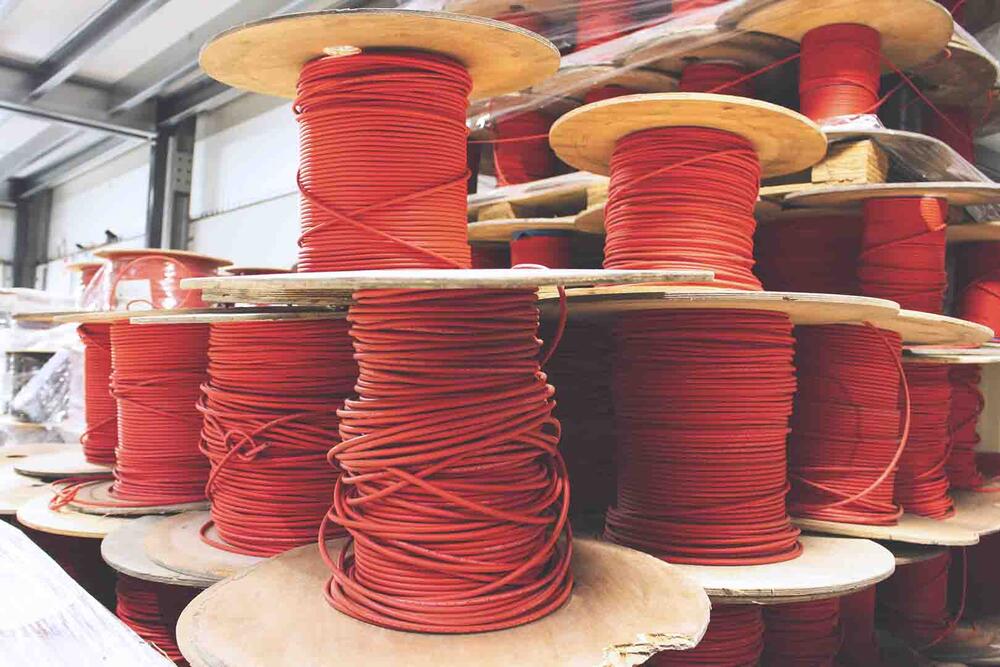

Leftover inverter cables accumulate

As ExtraPower’s installers cannot accurately predict in advance how many metres of inverter cable will be required, they usually bring a full reel of 1,000 metres to the site. In practice, only part of this cable is used, leaving hundreds of metres of leftover cable. In anticipation of a suitable solution, these leftover cables have been accumulating in ExtraPower’s warehouses, at least until recently.

WAAK Cable Assembly processes ExtraPower’s solar cable surpluses

Solar parks consist of long rows of solar panels. Not only are the panels connected to an inverter, but they are also interconnected using jumper cables. ExtraPower came up with the idea of cutting the large quantities of leftover inverter cable into jumper cables of 4 to 6 metres in length. As ExtraPower lacked both the capacity and the machinery to do this, they sought a partner to take on the task. Enter: WAAK Cable Assembly.

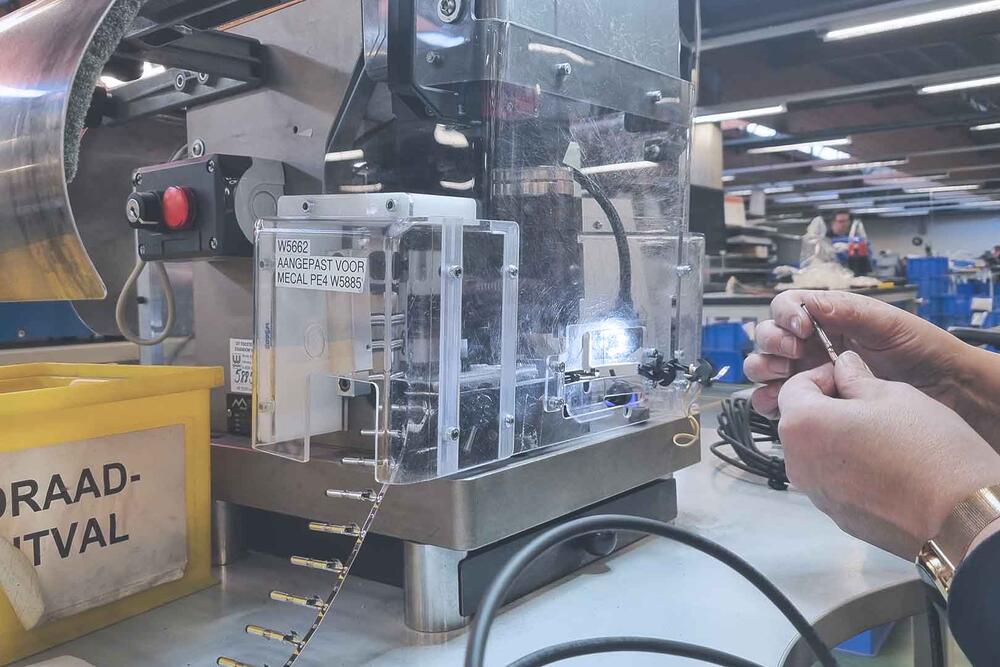

WAAK Cable Assembly: From inverter cables to jumper cables

In addition to cutting inverter cables, WAAK Cable Assembly employees also crimp special contacts designed specifically for solar panels. The jumper cables are then equipped with dedicated housings and are electrically tested. Finally, the completed cables are packaged and shipped to ExtraPower, whose installers can deploy them on-site as a ready-to-use, plug-and-play solution.

Ecological and economic benefits

This approach offers multiple advantages. Installers no longer need to cut cables on-site in potentially adverse weather conditions, nor do they need to carry heavy tools. In addition to saving time, it reduces the risk of errors and simplifies the installation process.

Moreover, there are clear financial and environmental benefits. By repurposing existing stock that would otherwise remain unused or be stripped for copper, materials are monetised. They take up less storage space, and the need for new, costly raw materials is reduced.

Growing interest in circular economy

We observe that more and more companies show interest in the opportunities offered by the circular economy. It not only creates financial benefits, but also helps them achieve their sustainability goals.

In doing so, companies not only make their own businesses more sustainable, they also encourage their customers and suppliers to make their operations sustainable. In this way, sustainability begins to permeate the entire supply chain.

Circularity: challenging but worth the effort

As an experienced industrial partner and circular economy advocate, we’re often told that it is difficult to launch profitable circular projects, which is an understandable concern. To partners wishing to engage with circularity, we advise starting small and looking for the low-hanging fruit.

The ExtraPower project is a textbook example of this. Bart Stock, Purchase Manager at ExtraPower, explains: “This project has not required major interventions in terms of manpower, costs, or time, yet its impact is significant for both our company and for the environment. It is a win-win situation in all areas. Although the project has only just been launched, we can already see tangible results. We therefore plan to take a closer look at all our production processes to determine whether we can initiate similar projects.”

We are pleased to receive such signals. We are keen to support ExtraPower and other potential partners in their circular journey by thinking along with them and helping them with the realisation and implementation of their circular ideas.