WAAK Cable Assembly: Reliable wire harness, pump and power cable solutions

In modern HVAC, automotive, and industrial applications, reliability is not optional, it’s essential. Every installation, machine, or vehicle only performs optimally when its internal wiring functions exactly as designed. WAAK Cable Assembly provides that reliability with high-quality cable solutions. With a team of 700 employees, WAAK produces wire harnesses, pump cables, and power cables for leading domestic and international customers. These serve a wide range of industries, including HVAC, utilities, and automotive.

Specialist in assemblage van kabelbomen, power cables en pompkabels

WAAK Cable Assembly specialises in assembling cables and wire harnesses for multiple applications, primarily in the HVAC-R market (Heating, Ventilation, Air Conditioning, and Refrigeration). Typical examples include heat pumps, ventilation systems, and central heating boilers. Our cables and cable harnesses are also used in electric vehicles, EV charging stations, and industrial machinery.

In addition, we assemble pump cables, which – like wire harnesses – are often used in HVAC and sanitary applications. Pump cables supply electrical power to pumps within HVAC systems. These pumps are essential for circulating fluids (such as water or coolant) throughout the system, thus ensuring an efficient distribution of heat or cold. For example, in water heaters, a circulation pump powered by pump cables pushes hot water from the boiler to radiators or underfloor heating.

Find out how this process works for heat pumps

Finally, we manufacture a wide range of power cables for medium- and low-voltage applications, such as those used in cables for smart digital meters and meter banks or solar panels (solar panels generate low-voltage direct current).

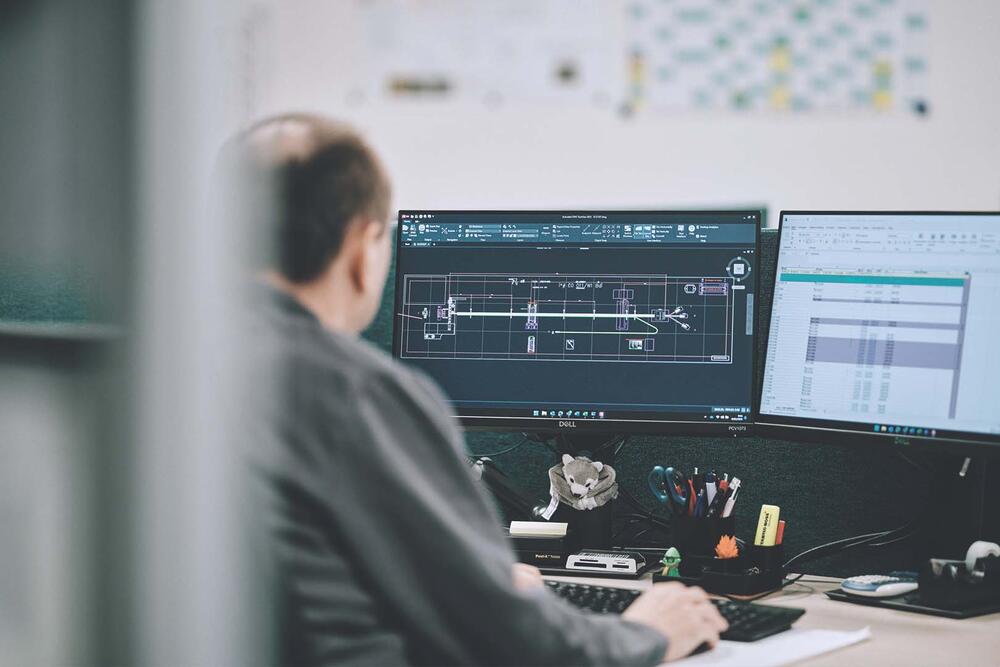

Added value through co-engineering

WAAK is more than a supplier of HVAC cables. Through our engineering department, we provide customers with unique added value. From the initial design stage, our engineers collaborate closely with the customer to optimise the manufacturability and efficiency of their design. This co-engineering process helps prevent errors and enhances the overall quality of the final product.

Our core strengths:

- Reliability: Consistent quality and on-time delivery. We deliver the exact quantities required, precisely when needed.

- Production capacity: We have the capacity to produce not hundreds but thousands of cables per order – all meeting the same high-quality standards.

- Co-engineering: Together with our customers, we optimise their designs so that the end product not only meets but exceeds expectations.

Ensuring quality at every stage of the production process

Quality control is embedded in every stage of our production process. Following the co-engineering phase, the production process is meticulously defined, including the development of tooling and work methods - tailored to both the complexity of the product and the capabilities of our employees. Once the customer provides final approval, we proceed to serial production.

Learn how we turn complex tasks into manageable, high-quality work

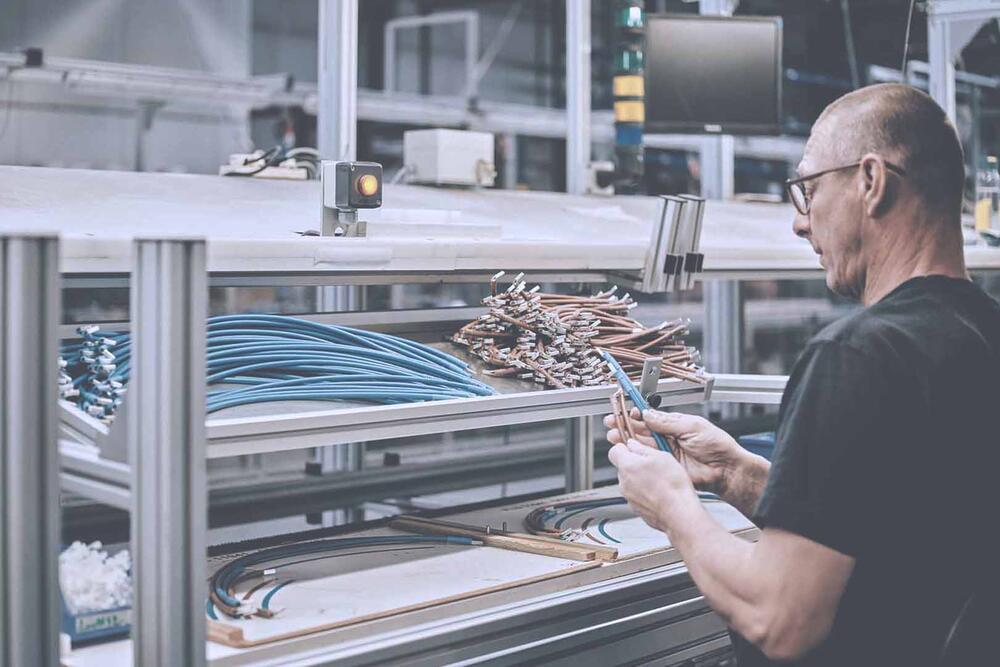

During production, cables, pump cables, power cables, and wire harnesses are classified and sorted according to type, before being processed on dedicated production lines.

From cutting cables to length and overmoulding, through wire harness assembly to final testing, each step is monitored using high-tech measurement and testing systems, such as camera control systems and electrical tests. Intermediate and final quality controls ensure that every product fully complies with the technical specifications and perfectly matches the customer’s requirements.

WAAK: Your trusted cable assembly partners

WAAK Cable Assembly is more than just a manufacturer of cables and wire harnesses. Partnering with WAAK means working with a team that thinks alongside you, prevents errors, and consistently delivers on its promises – in the right quantities, on time, and with WAAK’s renowned high-quality reliability.

Our strict production processes and quality control systems, combined with a proactive, co-engineering approach, guarantee flawless, error-free results. This is why customers keep choosing WAAK Cable Assembly for their wire harness, pump cable, and power cable needs, time and time again.