How to ensure water and gas tightness in HVAC cable harness production

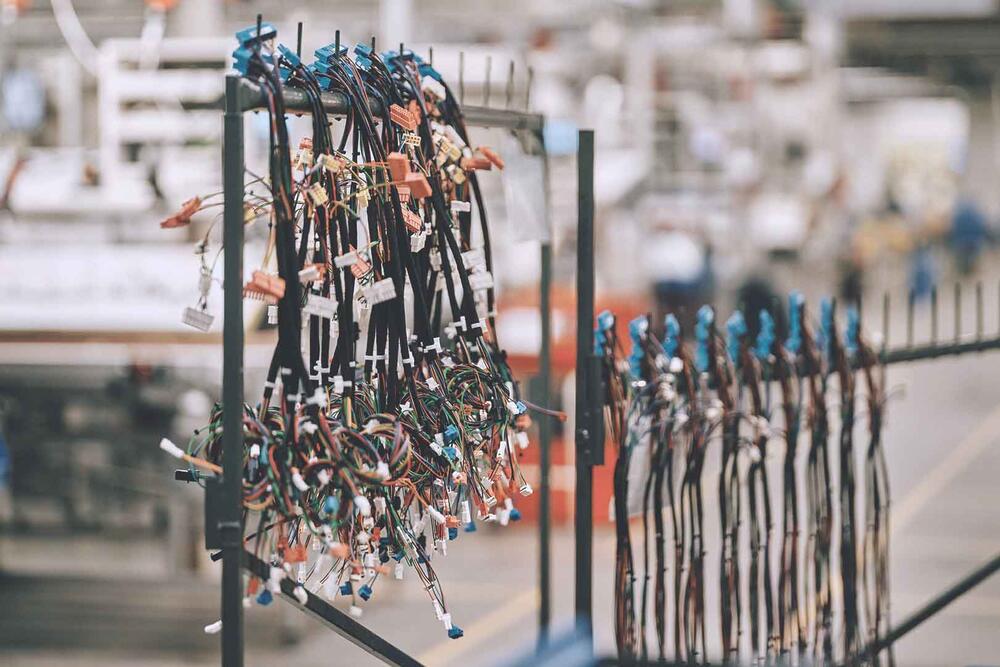

From air conditioning systems to heat pumps, solar shading, and (electric) cars, all these products contain complex wire harnesses. Due to stringent safety regulations, zero-defect has become the industry standard in HVAC and (e-)automotive sectors. In this context, the reliability and durability of cable harnesses are crucial. Additionally, these devices are often used in challenging environments, exposing them to moisture and dust. Products like aircons and heat pumps also contain gases such as the propane-based cooling agent R290 – which can be hazardous when combined with electricity. As specialist in cable harness manufacturing, we understand these conditions and consistently deliver solutions that meet the highest standards for water and gas tightness. This article outlines the key concepts, techniques, and quality control processes we apply to ensure that our cable harnesses meet the customers’ requirements.

Water and gas tightness in HVAC cable assembly

What is water tightness?

Given the fact that this article focuses mainly on the HVAC industry, water tightness should be defined as the ability of a system, component or enclosure to prevent water ingress under operational or environmental conditions.

When discussing water tightness, it is essential to specify the required level of protection. For this purpose, the International Protection Rating (IP Rating), also known as Ingress Protection Rating, is commonly used. This standard defines the degree of protection against the ingress of water into solid objects.

For example: an IP54-rating means:

- 5: Protected against dust ingress. Complete protection is not guaranteed, but dust levels will not interfere with the product’s proper functioning.

- 4: Protected against water splashes from any direction (tested with 10 litres of water per minute).

Learn more about how you can achieve water and gas tightness in HVAC cable assembly:

What is gas tightness?

Gas tightness is a more complex concept than water tightness. In the context of HVAC, gas tightness refers to the ability of a system, component, or enclosure to prevent the leakage of gases under operational or environmental conditions. HVAC applications often involve gases, such as the propane-based cooling agent R290 used in heat pumps and air conditioning systems - which can be hazardous when combined with electricity.

Unlike water, there is no universally accepted standard such as the IP rating. Instead, it is necessary to define an acceptable gas concentration level in a specific environment, considering the ventilation possibilities and safety regulations.

Complete gas tightness is possible but often unnecessary. The required degree of gas tightness should be determined by the manufacturer, based on the specific context in which the application is used and supported by a thorough risk analysis.

Important: Gases can migrate not only through physical gaps but also through cables or wires, from one compartment to another. Always keep this in mind and consult an expert when in doubt.

Solutions to achieve water and gas tightness

1. Cable glands

Cable glands are widely used to protect cables and wire harnesses against water ingress. Each cable gland has specific characteristics and therefore its own IP rating. When installing cable glands, it is important to:

- Select the right cable gland – is determined by the cable diameter

- Position the gland correctly

- Apply the proper torque during installation

At WAAK, we always check this within the customer’s design and verify whether the chosen cable gland meets the necessary specifications.

For gas tightness, it is insufficient to solely use cable glands. When working with explosive gases, it may be necessary to use EX-rated (explosion-proof) glands, which provide a higher level of gas containment. When in doubt about this, always consult an expert!

2. Sealed connectors

Another common solution for water tightness is the use of connectors with integrated seals. This is frequently used in HVAC applications to connect pumps for example. There are various types on the market, tailored to different cable diameters. It is important to install the connector correctly and accurately, as the wire, contact and seal should fit together perfectly. Once properly installed, the connector ensures effective watertightness.

3. Overmoulding HVAC cables and wire harnesses

Overmoulding is a technique where a connector and/or cable is encapsulated in a protective layer of plastic or rubber. This method offers multiple advantages:

- Protection: Shields the connector from dust, moisture, and other environmental factor.

- Mechanical strength: Increases resistance to bending and pulling.

- Reliability: Minimises the risk of loose or damaged connections.

- Aesthetics: Provides a clean, professional appearance.

Overmoulding can be used to form a grommet on a cable or wire harness, serving as a seal, feed-through, or strain relief.

Overmoulding is the most effective when applied to a pre-sealed connector. Using a custom-made mould developed by WAAK, the process can be completed in onesingle step, ensuring optimal protection against water ingress.

For open connectors, a multi-step process is required to achieve full encapsulation. In this case, at WAAK, we commonly use an angled or straight FCI connector. We typically use this type of connector to connect the PWM signal to a speed-controlled water pump.

If you like to know more about the overmoulding of HVAC cables and wire harnesses, make sure you check out the dedicated article.

How to Test for Water and Gas Tightness in cable assembly

For water tightness testing you can rely on international standards. Gas tightness in cable assembly however requires specific case-by-case testing.

As this requires a specialised expertise, WAAK supports its customers by providing small-scale test setups to evaluate new concepts. This approach enables an early detection of potential issues, which in turn minimises the need for costly modifications at a later stage.

Read the full article and learn how you can achieve water and gas tightness in HVAC cable assembly:

We have all the expertise you need!

Kristof Hots

Director Sales & Marketing

M: kristof.hots@waak.be

T: +32 56 36 34 34